The effectiveness of sterile packs is a key part of ensuring surgical safety. The object of its use is the patient, and if there is microbial contamination, it may lead to infections and other complications, affecting the patient's therapeutic effect and recovery, and in serious cases, it may be life-threatening.

How to confirm the validity of instrument pack sterility?

Integrity of instrument packages

When it comes to checking the integrity of device packages, we have to understand the packaging and packaging materials first.

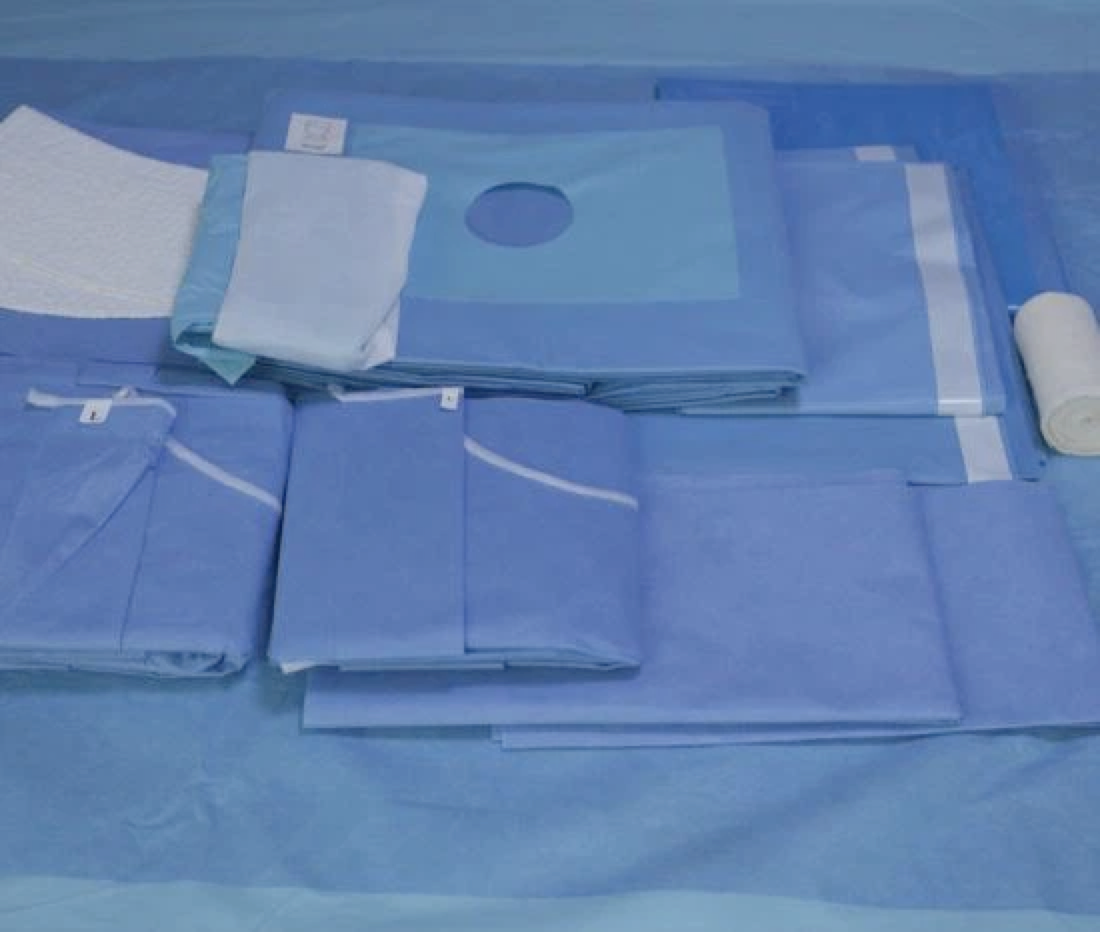

Packaging is an important means to ensure the sterility of the device from sterilization to use. According to the characteristics of the device, selecting suitable packaging materials and adopting corresponding packaging technology to wrap, close or seal the device. Therefore, all sterile articles should have intact packaging, and there is no qualified packaging without qualified sterile articles.

Medical packaging materials are mainly divided into two categories: soft packaging materials and rigid packaging materials. The former includes: cotton, non-woven, paper-plastic bags, etc.; the latter mainly refers to rigid containers.

Cotton cloth: reusable, should be cleaned once used. Check for stains and tears before use.

Non-woven fabric: single use. Check the appearance for holes, looseness and contamination before use.

Paper-plastic bag: Single-use. Before use, check the appearance for holes and cracked seals.

Rigid container: reusable. Before use, check whether the appearance is deformed, dented, defective, whether the outer cover of the filter membrane is loose; whether the latch closure is intact and flexible, whether the disposable latch is cracked; whether the sealing ring and the filter membrane are intact and unbroken.