According to the cause of non-woven fabric can be divided into eight categories

(1) spunlaced non-woven fabric: the high-pressure micro-water jet to a layer or multiple layers of fiber network, so that the fibers intertwine with each other, so as to strengthen the fiber network.

(2) thermal nonwoven fabric refers to adding fibrous or powdery hot-melt bonding reinforcement materials into the fiber net to make the fiber net melt and then cool after heating to strengthen the fabric.

(3) pulp airflow into the net non-woven fabric: also known as dust-free paper, dry papermaking non-woven fabric. It is the use of airflow into the net technology will be wood pulp fiber into a single fiber, with airflow to make the fiber agglutinate in the net curtain and then reinforce into cloth.

(4) wet non-woven fabric: the fiber raw material in the water medium is loosened into a single fiber, and the different fiber raw material is mixed, and the fiber suspension slurry is delivered to the net forming mechanism, and the net is strengthened into cloth under the wet state.

(5) spun-bonded non-woven fabric: after the polymer is extruded and stretched to form a continuous filament, laid into a net, the fiber net after bonding or mechanical reinforcement, into a non-woven fabric.

(6) melt-blown nonwoven fabric: the production steps are polymer input - melt extrusion - fiber formation - fiber cooling - mesh formation - reinforcement into cloth.

(7) Needling non-woven fabric: it is a kind of dry non-woven fabric. It uses the puncture effect of the needle to reinforce the fluffy fiber net into cloth.

(8) stitched non-woven fabric is a kind of dry non-woven fabric, the use of warp knitting coil structure of fiber net, yarn layer, non-textile materials (such as plastic sheets, etc.) or their combination of reinforcement made of non-woven fabric.

Characteristics of nonwoven fabric

It is moisture-proof, breathable, elastic, lightweight, non-combustion-supporting, easy to decomposable, non-toxic and non-irritating, colorful, low price, recycling and reuse, so it is widely used in many fields.

Use of non-woven fabric

In industrial materials, non-woven fabrics have high filtration efficiency, insulation, thermal insulation, acid resistance, alkali resistance, tear-resistance, and other characteristics, and are often used in the production of filter media, sound insulation, electrical insulation, packaging, roofing, and abrasive materials and other products.

In the commodity industry, it can be used as core material for clothing, curtain, wall decoration material, diaper, travel bags, and so on.

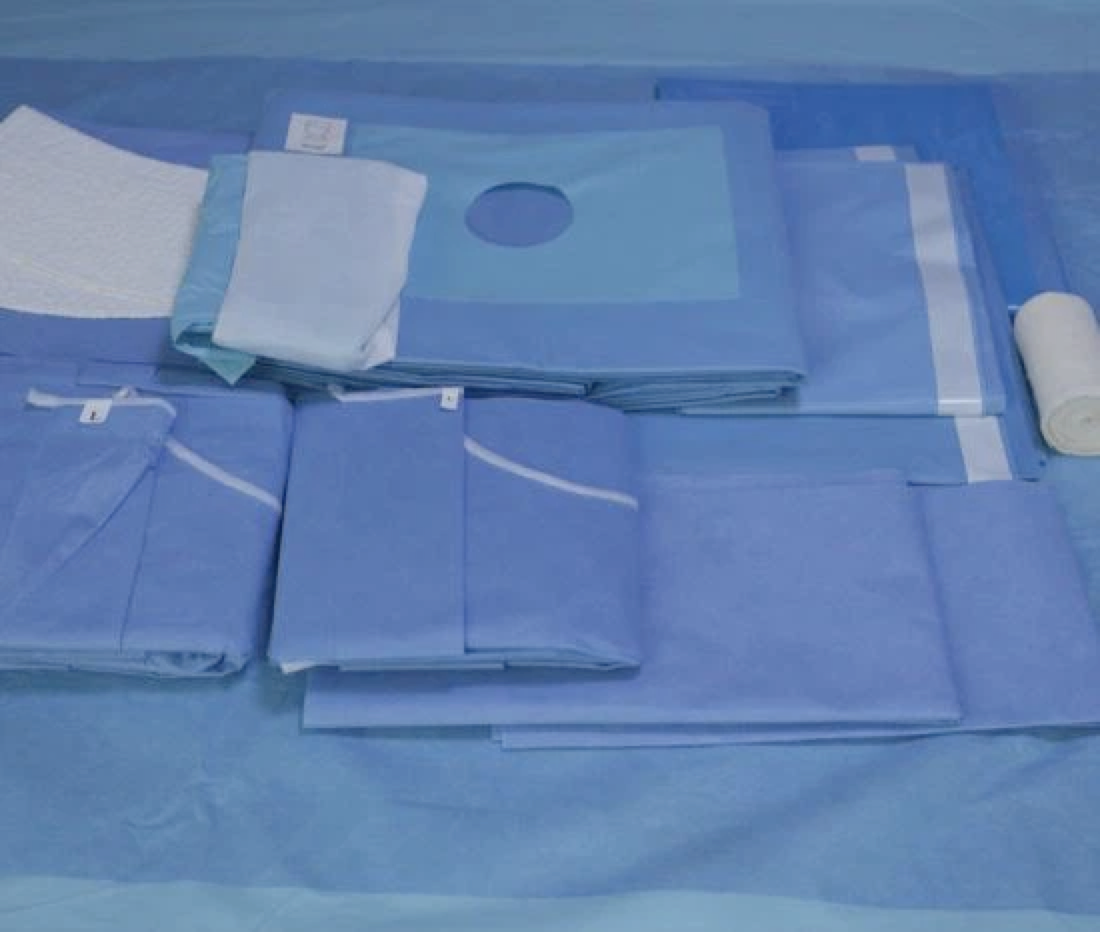

In medical and health products, it can be used for the production of operating gowns, disease gowns, masks, sanitary belts, etc.

Contact us: sales@hnmedtech.com