Medical wraps are mainly used for packaging medical devices for pressure steam sterilization, ethylene oxide sterilization, low-temperature formaldehyde sterilization, or hydrogen peroxide low-temperature plasma sterilization.

For packaging medical devices for autoclaving, ethylene oxide sterilization, low-temperature formaldehyde sterilization, or hydrogen peroxide low-temperature plasma sterilization.

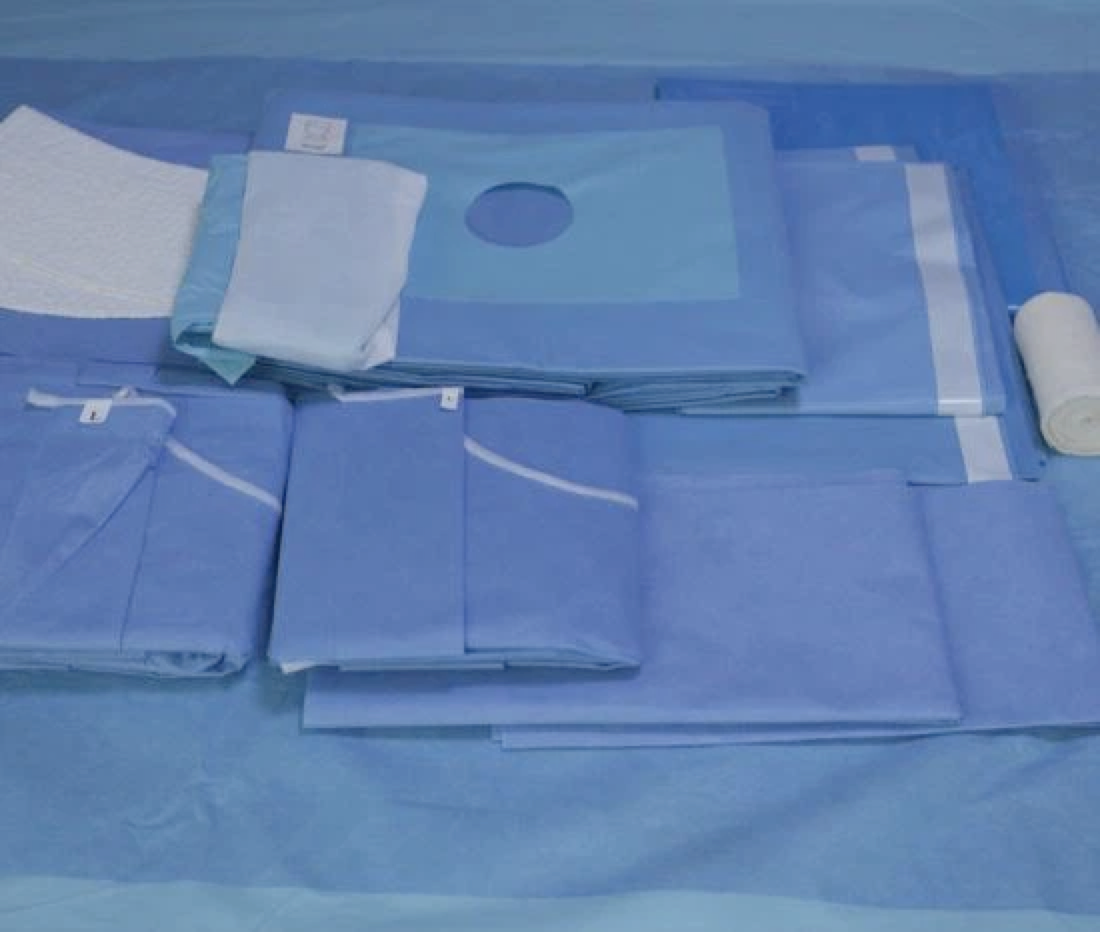

Medical wrapping can ensure that sterilized medical devices have effective microbial barrier performance and waterproof performance, no color fading, water resistance, strong air permeability, sterilization characteristics that facilitate the introduction and penetration of sterilization media, and good tensile strength. , tear resistance, puncture resistance, and other physical resistance properties. Soft and drapeable. Make sure the item does not bounce back when unpacked. Ensure the transportation, storage, and distribution of sterile products. Effectively prevent hospital cross-infection, reduce treatment costs, and improve infection control rates.

The hospital's new packaging materials such as rigid sterilization containers and non-woven fabrics are gradually replacing cotton cloth. The disposable filter paper and non-woven fabrics used in rigid sterilization containers have been tested for the bacteria resistance rate by the "Breathable Packaging Material Microbial Barrier Classification Test". It is better than double-layer cotton cloth, and the antibacterial effect of new cotton cloth is better than that of old cotton cloth, indicating that the antibacterial effect of cotton cloth is not ideal, and it will progressively decrease with the increase of washing times. After the cotton cloth was washed 31 times, the weight loss rate and tear strength decreased, but no pilling was found in the abrasion resistance test.

As a substitute for traditional cotton cloth, medical sterilization packaging non-woven fabric (SMS non-woven fabric) has been accepted and used by more and more hospital disinfection supply centers (CSSD) and is suitable for sterilization such as Steam, EO, Plasma, etc. Way. Medical sterilization packaging non-woven fabric is composed of two layers of spun-bond layer and one layer of melt-blown layer, which is anti-stab, anti-friction, and tear-resistant. It has physical resistance such as moisture resistance, low penetration rate, good air permeability, and strong water pressure resistance, which can effectively block the invasion of dust particles, alcohol, plasma, and other liquids, as well as bacteria and viruses.